PCB Assembly

Tatung Mexico has four Surface Mount production lines using Panasonic CM620 modular equipment. Use standardized equipment for all lines allows Tatung to minimize the lead time for product introduction and improve line utilization for capacity planning.

Tatung is highly capable of manufacturing both low-volume, high-mix (LVHM) and high-volume, low-mix (HVLM) PCB orders from prototype, pilot runs and to low, mid and high level capacities.

Component capability:

From 0402 (01005) chips to 90 x 100mm

Board size:

Up to 18" x 20" boards, thickness 0.5mm to 4mm

Inspection:

All assemblies have 100% AOI inspection performed

Component capability:

All types of components can be assembled following customer requirements

Board size:

Up to 20" wide boards

Soldering:

All machine offer lead free soldering

Functional Testing:

Test jigs and programs developed to follow customer design / software requirements

Line 1:

65,000 components per hour

Line 2 to 4:

110,000 components per hour

PCB Assembly:

BGA Repair

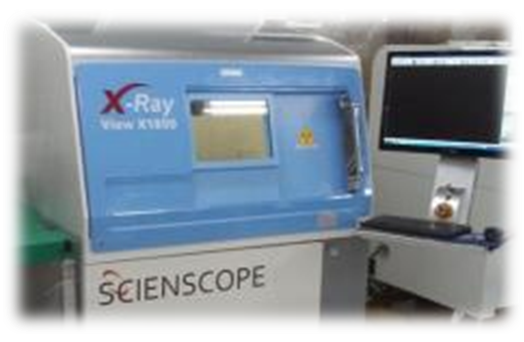

Tatung Mexico has highly trained engineers for performing BGA defects analysis and repair. An X-ray View X1800 machine is used for BGA defects analysis and a Wisdom show WDS-660 repair station is used for performing the necessary repairs.

Upper Heating Power

Lower Heating Power

Machine Dimension

Positioning Way

Temperature Control

PCB Size(Max)

PCB Size (Min)

PCB Blowup Diploid

Weight of machine

Thermocouple Ports

1200W

Second zone: 1200W,

Third zone: IR 4200W

L1200*W800*H900mm

V-shape card slot,

PCB holder can adjust by X and Y axes

K-type thermocouple closed loop control

450*450mm

10*10mm

2-50X

110Kg

3units

90kV – 5 micron focal spot X-Ray tube

Z axis movement of the x-ray tube and sample stage

Computer controlled variable speed X-Y stage

Mega pixel mapping camera with zoom window

16” x 18” stage 50o oblique angle viewing

Programmable computer controlled – variable speed X – Y stage

Language

Language Spanish (México)

Spanish (México)  TAIWAN

TAIWAN

NETHERLANDS

NETHERLANDS  L.A. CALIFORNIA

L.A. CALIFORNIA